Welders face many dangers while working. The most common hazards are:

Metallic fumes fill the air in a manufacturing plant.

In addition to UV arc welding, welders can create an invisible UV arc.

Particles can enter your eyes.

It ignites burns.

There is noise.

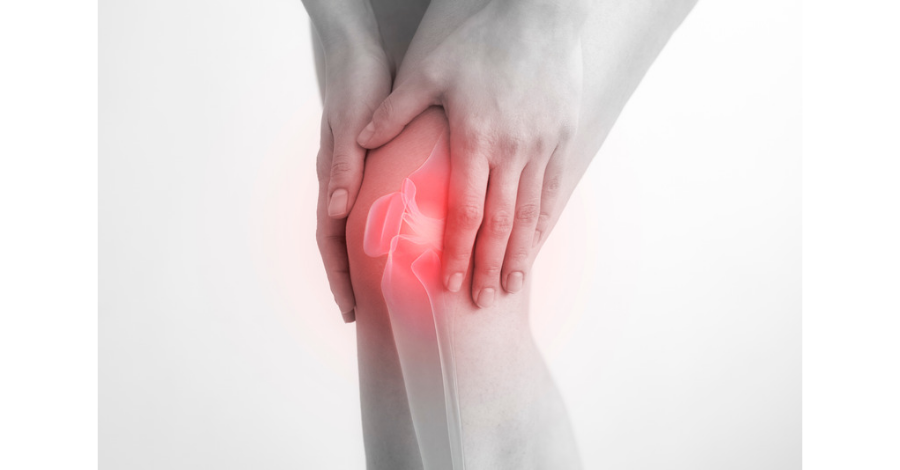

Out of all causes of Musculoskeletal Disorders (or MSCDs), working in uncomfortable conditions is the leading cause. This has been shown through many studies; one in particular found that welding carried a high risk of developing MSCDs.

While in uncomfortable positions such as squatting, kneeling or stooping, people experience discomfort due to restricted spaces.

Carry heavy objects or equipment.

If you keep your neck in a bent position, you should avoid straining your neck.

the height of the shoulders.

Wearning heavy welding masks and hard hats can increase the pressure on the neck.

The resulting medical issues include injuries to the back, neck, shoulder or knee.

Maximize ease and convenience – Ergonomics

20: Determine control – Analogies

Paraphrase: Maximize ease and convenience – Analogies

21: Determine control – Geometrics

Paraphrase: Maximize ease and convenience – Geometrics

22: Determine control – Graphics

Paraphrase: Maximize ease and convenience – Graphics

Welding-related MSDs can be prevented by avoiding or reducing the consumption of:

Extreme exercise, such as lifting heavy weights, causes fatigue.

Standing still for too long can cause posture problems.

Reduce the intensity of the colors.

Self-darkening lenses eliminate the need to constantly close and open the helmet once the arc is struck.

Eliminate neck pressure by reducing the size of the head.

You should use mechanical lifting equipment whenever possible when moving materials or components.

Avoid unnecessary lifting by assembling parts and using material handling equipment.

Use the mobile lift table to transport materials from the closet to the workshop.

These tables can support material as it’s being loaded into the machine. A smaller table is available for use with smaller sheets or machines like press presses.

Tables with larger proportions can serve as a material input or press for breaking and bending.

Get help when lifting heavy objects.

Eliminate simple gestures from public art.

It should be placed between the waist and shoulder height.

Use wheeled turntables and elevators.

Utilize a welding torch with a two-handed swivel.

When your workload is light, sit on a task bench.

Working on the floor can be accomplished by sitting on a bench rather than leaning forward.

Attach swiveling clamps to both ends of your project.

Thread the welding cable onto the reel.

During the day, take breaks from stretches to alleviate pain and use the muscles.

Conclusion

Welders often suffer injuries to their back, neck, arms, hands, shoulders and chest. Ask your occupational healthcareprovider to list any issues they’ve had with these parts of the body.

The problems these approaches are meant to remedy are discussed in the text.

The EPI — Dietary Supplement — plays a significant role in the Dietary Diagnostic System — DDS.

Before starting work, employees should hear safety talks so they understand the HSE’s management tools.

The hypothetical service front’s content is only meant to give an understanding of the nature of a proposed service. Therefore, all generic safety talks must be modified to fit the work fronts by a company’s HSE professional (Environment, Health and Safety) or sector leaders. Only the person speaking during the Safety Talks is solely accountable for the work.

0 Comentários